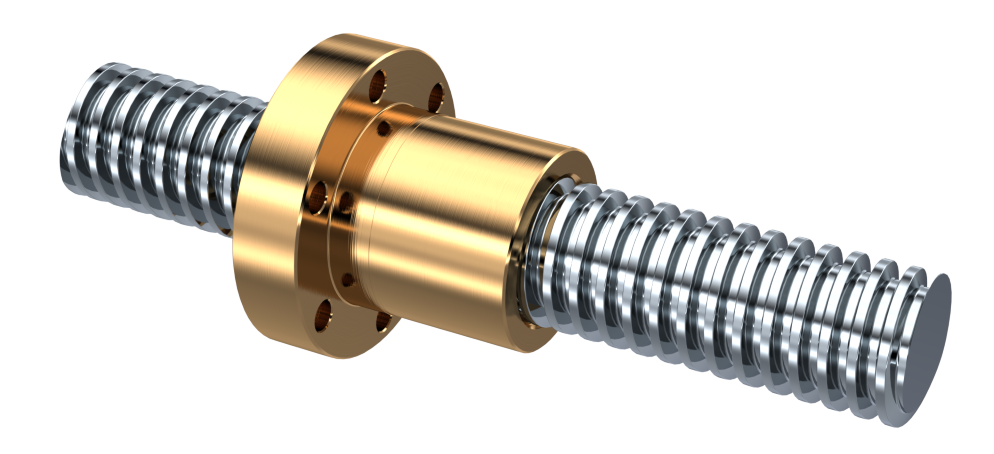

Product Description

| Precision | C7&C5 rolled,C5&C3 grinding |

| Model | SFK,SFU,DFU,SFE,SFS,DFS,SFI,DFI,SCI |

| Size customize | Available |

| Maximum length | 100MM~7500MM,different diameter maximum length are different |

| Raw Materail | 50Crmo4,S55C,SCM420H |

| HS CODE | 8483900090,8483457100 |

| Items packing | Plastic bag+Cartons+Plywood boxes.According to our customer’s request. |

| Payment terms | L/C,TT,Western Union |

| Production lead time | Base on customer requirement quantity,by negotiated |

| Samples | Bearings sample and catalogue available |

| Application | CNC machines,machine tools,Industrial Machinery,Pringting Machine,Paper-processing machine,automatic machines,textiles machines,electronic machinery,transport machinery,Robot,etc |

Detailed Photos

Certifications

FAQ

1.How To order?

1,please tell us what model and quantity you need;

2.then we will make a Pl for you to confirm the order details;

3.when we confirmed everything, can arrange the payment;

4. finally we deliver the goods within the stipulated time.

2.what’s the dellvery tlme?

The delivery time will depends on the quantity that you need, it’s usually 7-14 days.

3.How to get the prlce faster?

Contact with us, give us your requirements, of course it’s better that you can givepicture or drawing or original No.

3.When can we get the reply?

Any inquiries will be replied within 24 hours.

4.what’s your payment terms?

T/T,Paypal,Western Union,Trade Assurance Order and etc. of course, other paymentmethod can be negotiated.

5.How to contact us?

send your inquiry details in the below, click “send” now! free sample and best priceare waiting for you, if you can’t find the product in our web, you can also send aninquiry to us, even if we don’t make it, we will find the same product with goodquantity and good price.

6.can l get some samples?

Yes, sample order is aviliable for the quantity check and market test, you can contactwith us for some free sample with freight collect. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Screw Diameter: | 11-20mm |

| Flange: | Without Flange |

| Nut Number: | Single |

| Rows Number: | 4-Row |

| Nut Type: | Circulator |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that use lead screws for precise positioning?

Lead screws are widely utilized in various products and machinery that require precise positioning. Here are some examples of products and machinery that commonly use lead screws for precise positioning:

- CNC Machines: Computer numerical control (CNC) machines, including CNC mills, lathes, and routers, use lead screws to precisely position the cutting tools or workpieces. Lead screws enable accurate and repeatable movement in the linear motion systems of these machines, allowing for precise machining operations.

- 3D Printers: Lead screws are extensively used in 3D printers to control the movement of the print head or build platform. They enable precise positioning of the print head, ensuring accurate layer-by-layer deposition of the printing material, resulting in high-quality 3D prints.

- Robotics: Lead screws are integral to robotic systems that require precise positioning. They are used in robotic arms to control the movement and positioning of the end effectors or grippers. Lead screws provide accurate and controlled linear motion in robot joints, allowing for precise and coordinated movements in industrial, medical, and research robotics.

- Medical Imaging Systems: Lead screws are employed in medical imaging systems, such as computed tomography (CT) scanners and magnetic resonance imaging (MRI) machines, to precisely position the patient bed or gantry. This precise positioning is crucial for accurate imaging and diagnosis.

- Laboratory Automation Equipment: Lead screws are used in laboratory automation equipment, such as liquid handling robots and sample handling systems, for precise positioning and movement of samples, reagents, and labware. They ensure accurate and repeatable positioning required for various laboratory processes.

- Semiconductor Manufacturing Equipment: Lead screws are utilized in semiconductor manufacturing equipment, including wafer handling systems and lithography machines. They provide precise positioning and movement of wafers, masks, and other components critical for semiconductor fabrication processes.

- Camera Sliders: Lead screws are employed in camera sliders used in photography and videography applications. They enable smooth and precise linear motion of the camera along the slider, allowing for controlled tracking shots and precise camera positioning.

- Telescopes and Astronomy Equipment: Lead screws are utilized in telescopes and other astronomy equipment to precisely position optical components and achieve accurate tracking of celestial objects. They enable fine adjustments and precise pointing of telescopes for astronomical observations.

- Industrial Inspection Systems: Lead screws are used in industrial inspection systems, such as coordinate measuring machines (CMMs) and optical inspection systems, for precise movement and positioning of the inspection probes or cameras. This ensures accurate measurement and inspection of manufactured components.

These are just a few examples of the products and machinery that utilize lead screws for precise positioning. The versatility, accuracy, and reliability of lead screws make them a preferred choice in applications that require controlled linear motion and precise positioning of components.

Are there innovations or advancements in lead screw technology that have emerged in recent years?

In recent years, there have been notable innovations and advancements in lead screw technology aimed at improving performance, efficiency, precision, and durability. These advancements have been driven by the demand for more sophisticated machinery and automation systems. Here are some key innovations in lead screw technology that have emerged in recent years:

- Anti-Backlash Designs: Backlash, which refers to the play or clearance between the screw and nut, has been a longstanding challenge in lead screw systems. To address this issue, innovative anti-backlash designs have been developed. These designs incorporate mechanisms such as preloading systems, split nuts, or adjustable axial play to minimize or eliminate backlash, resulting in improved precision and repeatability.

- High-Efficiency Thread Profiles: Traditional lead screws often feature trapezoidal or ACME thread profiles, which can result in higher friction and lower mechanical efficiency. Recent advancements have introduced new thread profiles, such as the “triangular” or “wedge” profiles, which optimize the contact area between the screw and nut, reducing friction and improving mechanical efficiency. These high-efficiency thread profiles offer smoother operation, increased load-carrying capacity, and improved energy efficiency.

- Lead Screw Coatings and Surface Treatments: Coatings and surface treatments have been developed to enhance the durability, wear resistance, and lubrication properties of lead screws. For example, advanced coatings like Teflon, ceramic, or DLC (Diamond-Like Carbon) coatings provide low friction, reduce wear, and improve the lifespan of the lead screw. These coatings also help prevent contaminants from adhering to the surfaces, minimizing the risk of damage or performance degradation.

- Integrated Lubrication Systems: Lubrication is crucial for smooth operation and longevity of lead screws. Recent advancements have introduced integrated lubrication systems that automatically deliver a controlled amount of lubricant to the screw and nut. These systems ensure consistent and optimal lubrication, reducing friction, wear, and the need for manual lubrication maintenance. Integrated lubrication systems can be particularly beneficial in applications where access to the lead screw is limited or in environments where contamination risks are high.

- Smart and Connected Lead Screw Systems: The rise of Industry 4.0 and the Internet of Things (IoT) has led to the development of smart and connected lead screw systems. These systems feature embedded sensors, communication capabilities, and data analytics algorithms. They enable real-time monitoring of operating parameters, condition monitoring, predictive maintenance, and performance optimization. Smart lead screw systems provide valuable insights, enhance operational efficiency, and reduce downtime by enabling proactive maintenance and troubleshooting.

- Hybrid Lead Screw Technologies: Hybrid lead screw technologies combine the advantages of different types of screws, such as combining a traditional lead screw with a ball screw or roller screw elements. This fusion results in enhanced performance characteristics, such as increased load capacity, improved efficiency, reduced friction, and higher precision. Hybrid lead screws offer a cost-effective alternative to high-precision ball screws while providing superior performance compared to traditional lead screws.

These recent innovations and advancements in lead screw technology have significantly improved the performance, efficiency, precision, and durability of lead screw systems. Anti-backlash designs, high-efficiency thread profiles, advanced coatings, integrated lubrication systems, smart and connected features, and hybrid technologies have expanded the capabilities and application range of lead screws in various industries, including aerospace, automotive, robotics, and industrial automation.

Are there specific advantages to using lead screws over other linear motion systems?

Yes, there are specific advantages to using lead screws over other linear motion systems. Here are some of the advantages associated with lead screws:

- Precision and Accuracy: Lead screws offer precise and accurate linear motion control. The thread design and pitch allow for precise positioning and movement of components, making them suitable for applications that require high levels of accuracy and repeatability.

- Cost-Effectiveness: Lead screws are often more cost-effective compared to other linear motion systems, such as ball screws or linear actuators. They provide a reliable and efficient solution for converting rotary motion into linear motion at a relatively lower cost, making them a popular choice for many applications.

- High Load Capacity: Lead screws are capable of handling significant axial loads and torque. The thread engagement between the screw and nut distributes the load over a larger surface area, allowing lead screws to support and transfer substantial loads. This makes them suitable for applications that require heavy-duty performance and load-carrying capabilities.

- Self-Locking: Lead screws have a self-locking characteristic, which means they can hold their position without the need for additional locking mechanisms. The friction between the mating threads helps prevent back-driving and maintains the position of the load, providing stability and safety in applications where holding the position is critical.

- Simple Design and Installation: Lead screws have a relatively simple design, consisting of a screw and a nut. This simplicity makes them easier to install and maintain compared to more complex linear motion systems. Additionally, the straightforward design allows for customization and modification to meet specific application requirements.

- Efficiency: Lead screws can achieve high mechanical efficiency in converting rotary motion to linear motion. The efficiency depends on factors such as the thread design, lubrication, and preload. With proper design and lubrication, lead screws can operate with minimal friction and energy loss, ensuring efficient power transmission.

- Versatility: Lead screws can be used in a wide range of applications across various industries. They are suitable for applications that require linear motion, precise positioning, or adjustment of components. Lead screws find applications in industries such as manufacturing, automation, robotics, aerospace, medical, and more.

These advantages make lead screws a popular choice in many applications where precise linear motion control, cost-effectiveness, high load capacity, and simplicity are essential. However, it’s important to consider specific application requirements and factors such as speed, accuracy, duty cycle, and environmental conditions when selecting the appropriate linear motion system.

editor by Dream 2024-05-09

Leave a Reply